Fluidized Powder Coating Southeast Prince Manufacturing Asheville, NC

Fluidized Powder Coating

Fluidized powder coating is a highly efficient and versatile process used to apply a protective and decorative layer of powder coating onto various surfaces, particularly metal. This method utilizes a fluidized bed to suspend and evenly disperse the powder coating material, allowing for uniform coverage on complex shapes and intricate surfaces. Here’s an overview of the fluidizing powder coating process and its advantages:

Fluidizing Powder Coating Process:

-

Substrate Preparation: The surface to be coated is thoroughly cleaned to remove any contaminants, ensuring proper adhesion of the powder coating material.

-

Powder Coating Material: The powder coating material, typically a blend of pigments and resins, is placed in a fluidized bed. This bed consists of a container equipped with a porous membrane or diffuser plate at the bottom.

-

Fluidization: Compressed air is introduced through the diffuser plate, causing the powder coating material to become fluidized. This creates a “fluidized bed” where the powder particles behave like a liquid, allowing for easy and uniform coating.

-

Substrate Immersion: The preheated substrate is then immersed or lowered into the fluidized bed of powder coating material. The fluidized powder particles adhere to the heated surface, creating a thin, even coating.

-

Excess Material Removal: After coating, the substrate is typically allowed to cool briefly, and any excess powder that did not adhere is removed. This can be done through tapping, blowing, or vibrating the coated object.

-

Curing: The coated substrate is transferred to an oven for curing. The heat causes the powder coating to melt, flow, and form a continuous, durable finish on the substrate.

-

Cooling and Inspection: Once cured, the coated object is allowed to cool, and a final inspection is conducted to ensure the coating is uniform, adheres well, and meets desired specifications.

Advantages of Fluidizing Powder Coating:

-

Uniform Coverage: The fluidized bed ensures consistent and even coverage, even on complex or three-dimensional objects, resulting in a smooth and uniform finish.

-

Waste Reduction: Excess powder can be collected and reused, minimizing material waste and contributing to cost-effectiveness.

-

Durability: Fluidizing powder coatings provide a durable and resilient finish, offering resistance against chipping, scratching, and other forms of wear.

-

Quick Processing: The fluidizing process is generally quick, contributing to faster production turnaround times.

-

Versatility: Suitable for a wide range of substrates, including metals, plastics, and composites, making it a versatile solution for various industries.

-

Cost Efficiency: Reduced material waste, quick processing times, and efficient use of powder contribute to overall cost-effectiveness.

-

Even Coverage on Complex Shapes: The fluidized bed allows for even coverage on intricate and irregularly shaped surfaces, providing a consistent finish.

-

Environmental Friendliness: Powder coatings are generally more environmentally friendly than liquid coatings, with minimal VOC emissions and reduced hazardous waste.

-

Customization: A wide range of colors and finishes are available, allowing for customization based on aesthetic preferences.

-

Improved Edge Coverage: The fluidized powder coating process can provide improved coverage on edges and recessed areas, ensuring thorough protection.

Fluidizing powder coating is highly efficient and effective with advantages such as uniform coverage, waste reduction, durability, and versatility. Its application spans various industries, offering a superior finish that meets both aesthetic and functional requirements.

Applications where the fluidizing powder coatings are used

Fluidizing powder coating finds applications across a diverse range of industries and sectors due to its versatility, durability, and efficiency. Some notable applications include:

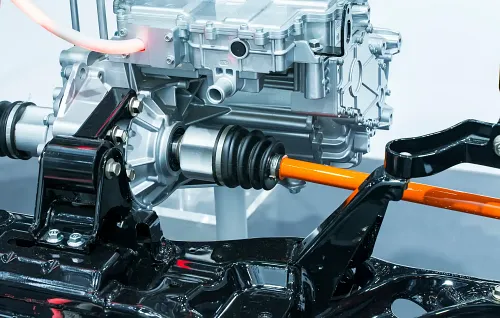

Automotive Industry:

Automotive Parts: Fluidizing powder coating is widely used for coating various automotive components, including wheels, chassis parts, engine components, and exterior trim. The durable finish helps protect against corrosion and wear.

Aerospace Industry:

Aircraft Components: Critical parts of aircraft, such as landing gear, engine components, and structural elements, benefit from fluidizing powder coating for its corrosion resistance and ability to withstand harsh environmental conditions.

Appliance Manufacturing:

Household Appliances: Major appliances like refrigerators, ovens, and washing machines often undergo fluidizing powder coating to achieve a durable and aesthetically pleasing finish.

Furniture and Fixtures:

Metal Furniture: Outdoor furniture, office furniture, and other metal fixtures are coated with fluidizing powder for protection against weathering, scratches, and other forms of wear.

Architectural Applications:

Aluminum Extrusions: Fluidizing powder coating is commonly used for coating aluminum extrusions used in architectural applications such as window frames, curtain walls, and other building components.

Industrial Equipment:

Machinery and Equipment: Various industrial equipment and machinery components benefit from fluidizing powder coating due to its ability to provide a durable and protective finish in demanding manufacturing environments.

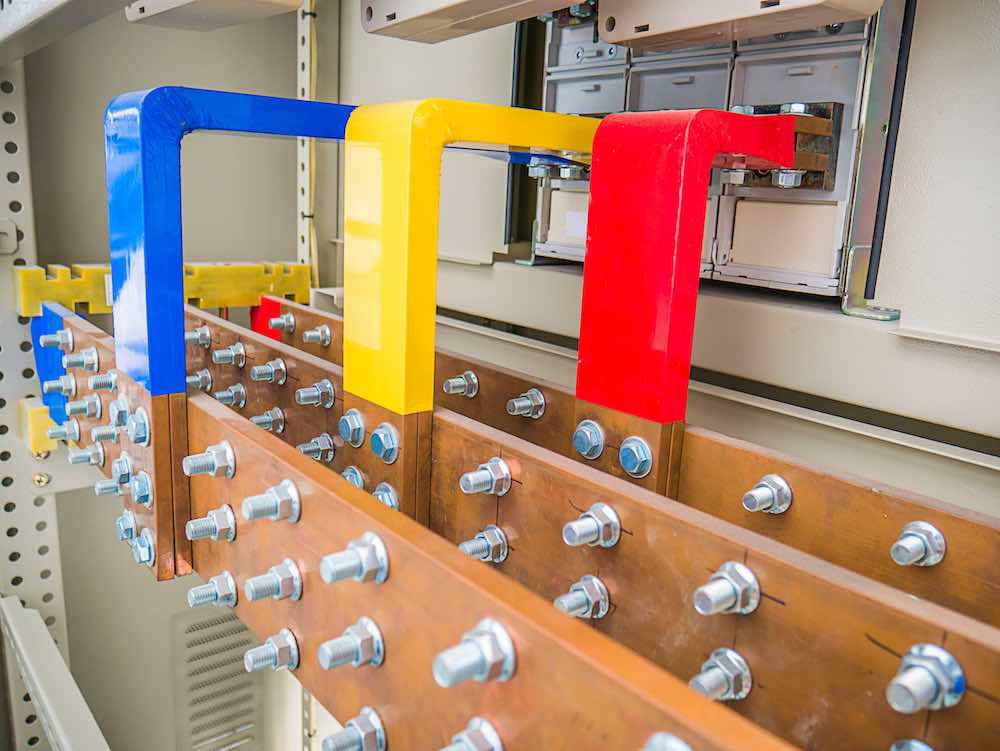

Electronics and Electrical Components:

Enclosures and Cabinets: Electronic enclosures, cabinets, and other metal components in the electronics industry are coated for corrosion resistance and improved aesthetics.

Outdoor Equipment:

Playground Equipment: Metal components of playground structures, park benches, and outdoor equipment are often coated with fluidizing powder for durability and resistance to weathering.

Medical Devices:

Medical Equipment Components: Certain medical devices and equipment, especially those with metal components, benefit from fluidizing powder coating for its protective and hygienic properties.

Consumer Goods:

Sporting Goods: Bicycle frames, exercise equipment, and other sporting goods often utilize fluidizing powder coating for their ability to withstand outdoor conditions and physical stress.

Oil and Gas Industry:

Pipes and Fittings: In the oil and gas sector, fluidizing powder coating is applied to pipes, fittings, and other metal components for corrosion protection, particularly in harsh and corrosive environments.

Energy Industry:

Renewable Energy Components: Wind turbine components, solar panel frames, and other renewable energy equipment benefit from fluidizing powder coating for its protective and long-lasting finish.

Retail Displays and Fixtures:

Store Fixtures: Metal store fixtures, shelving units, and displays often undergo fluidizing powder coating to enhance durability and maintain an attractive appearance.

Fluidizing powder coating has become a preferred choice in many industries because it provides a durable, uniform, and aesthetically pleasing finish while offering protection against corrosion and wear. The versatility of this coating process allows it to be applied to a wide range of materials and products, contributing to its widespread adoption across various sectors.

Transform the durability and aesthetics of your products with our superior fluidizing powder coating services. At Prince Manufacturing, we specialize in delivering precision and excellence in every finish, ensuring that your components meet and exceed industry standards.

Elevate your products’ resilience and visual appeal with our state-of-the-art fluidizing powder coating technology. Ready to redefine your manufacturing standards?

Contact us today, and let’s embark on a journey to enhance the performance and longevity of your valuable creations. Trust in our expertise to provide unmatched quality in fluidizing powder coating. Your success is our priority—connect with us now and experience the difference.

Contact us

Are you ready to discuss how we can help you achieve your manufacturing goals? Fill out this form and we will get back to you.

Prince Manufacturing Asheville

209 Broadpointe Dr.

Mills River, NC 28759

Phone: +1 803-918-5599

Metal Coating & Fabrication Services Serving the Southeast of the USA from our Asheville, NC Location

Already Trusted Us