Efficient and Reliable Contract Assembly Services Enhance your production with our expert assembly solutions, ensuring quality and efficiency at every step.

Comprehensive Contract Assembly

Prince Manufacturing offers comprehensive contract assembly services designed to streamline your production process. With decades of experience and advanced facilities, we provide reliable and high-quality assembly solutions that meet your specific needs.

Our Contract Assembly Services Include:

- Sub-Assembly: Expertise in assembling complex sub-components to streamline your final production.

- Final Assembly: Comprehensive final assembly services ensure your products are market-ready.

- Testing and Inspection: Rigorous testing and inspection processes to guarantee the highest quality.

- Packaging and Shipping: Efficient packaging and shipping solutions to meet your distribution needs.

See customer success and companies that already trusted us.

Contact us. Free Consultation about your goals.

Ready to take your business to the next level? Fill out the form below, and let’s discuss achieving your goals together!

Custom Assembly Solutions

You need trouble-free production, with individual components meshing together precisely as planned. You aim to bring the complexity of your processes down to manageable levels, focusing on core capabilities while keeping costs to a minimum, reducing waste, and increasing flexibility. We’re here to help by having your contract assembly outsourced to us.

Prince Manufacturing adds value to the supply chain by assembling metal fabricated parts and more. Our experience, knowledge, facilities, and capabilities allow us to assemble a variety of products and components, including circuit breaker assemblies, battery chargers, and power steering pumps, for example.

Benefits of Contract Assembly

The benefits of outsourcing contract assembly to our customers fall into three key strategic categories: cost, quality, and delivery.

- Cost Efficiency: We reduce costs and add value by streamlining the supply chain, eliminating waste, and minimizing the extra handling of parts. Our strategically located facilities provide access to lower-cost labor options, further driving down expenses.

- Quality Improvement: Our approach to quality is straightforward—fewer touchpoints mean fewer errors. By minimizing the handling of parts, we ensure higher quality and reduce the likelihood of defects.

- Optimized Delivery: By assembling components into complete units or products, we cut down on the costs and waste associated with delivery. This consolidation means our clients receive a single, comprehensive component instead of managing multiple parts, enhancing efficiency and reducing logistical complexity.

By leveraging these strategic benefits, Prince Manufacturing offers a comprehensive solution that supports your operational goals while maintaining the highest standards of cost-effectiveness, quality, and delivery performance.

State-of-the-Art Facilities

Prince Manufacturing operates six state-of-the-art factories across four strategic locations, enhancing their ability to deliver top-tier contract manufacturing services. In the United States, their advanced facilities are located in Garrett, Indiana, and Asheville, North Carolina. They also maintain a cutting-edge presence in El Paso, Texas, and expand their reach into Mexico with two high-tech plants in Ciudad Juárez and another in Monterrey.

These modern facilities specialize in various manufacturing processes, including metal fabrication, assembly, coating, and logistics. They ensure quality and efficiency while staying close to clients and optimizing operational costs.

At Prince Manufacturing, we know that while the process begins with fabrication, forming, stamping, and coating, it doesn’t end there. We have the facilities and the expertise to see the job through to the end—assembling parts into a component or a complete product. Through outsourcing contract assembly you rely on our expertise and strategic regional locations, we decrease the costs associated with delivery and inventory while, more importantly, ensuring significantly higher quality by eliminating steps and chances for error and reducing costs and waste in the supply chain. For more information about our capabilities in Assembly as a contract manufacturer strategic outsource, please contact us today. Read about all the benefits of outsourcing contract assembly to Prince Manufacturing. More Than A Shelter.

Already Trusted Us

Customer Success Examples

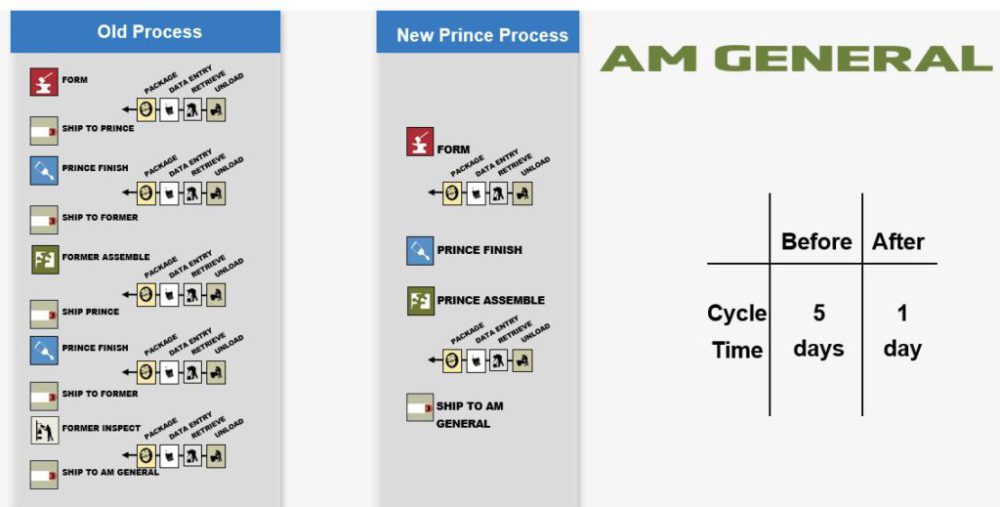

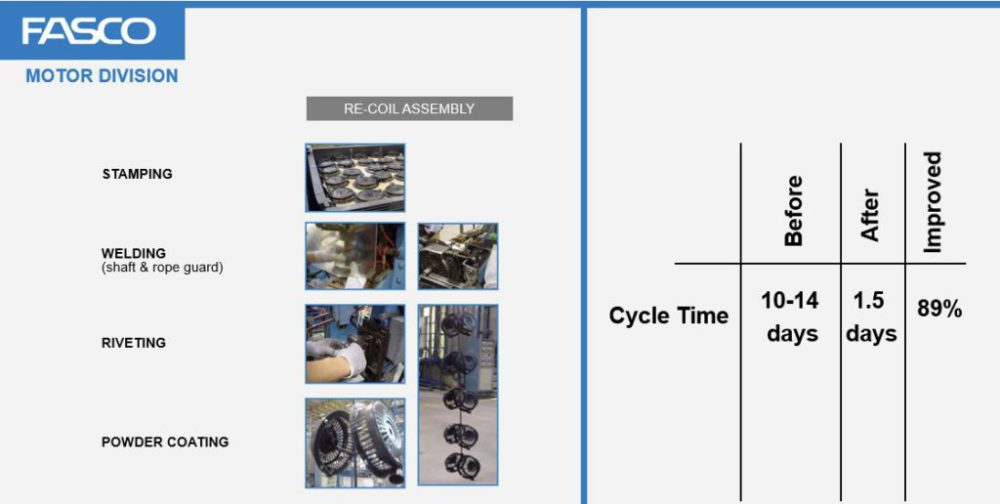

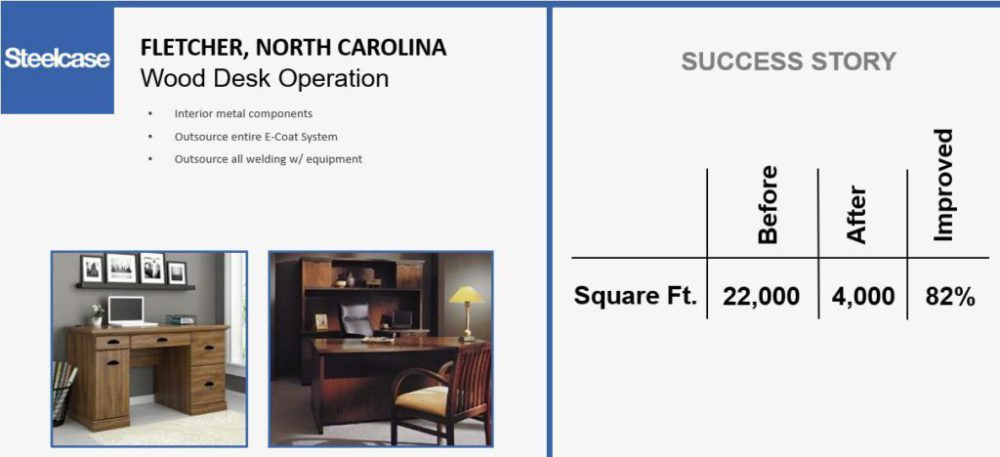

One customer saw their square footage requirement drop from 600,000 square feet to 200,000 and their cycle time drop from five days to one—in addition to the other savings they realized. Below you can see 3 of our customers success stories. We reduced AM General’s manufacturing process from taking 5 days to 1 day. Fasco Motor Division process was reduced by 89% in length. From 10-14 days we reduced it to 1.5 days. Steelcase saw 82% reduction in required warehouse space from 22,000 sq ft to 4,000 sq ft. These are just a few examples.

Our Core Contract Manufacturing Services

Contract

Metal Fabrication

Contract

Sheet Metal Forming

Contract

Metal

Stamping

Contract

Assembly

Services

Contract

E-coating

Services

Contract

Metal

Coating

Contract

CARC

Painting

Contract

Powder

Coating

Contract

Fluidized Powder Coating

Contract

Liquid

Painting

Contract

Metal

Plating

Contract

Sequencing

Services

Shelter Services

Manufacturing in Mexico

Contract

Process Outsource

Contract

Supply Chain Management

Contract