Metal Preparation Monterrey Prince Manufacturing Monterrey, Mexico

Degreasing, Phosphatizing

Metal Degreasing and Phosphatizing: Preparing Surfaces for Coating and Corrosion Protection

Metal degreasing and phosphatizing are essential pre-treatment processes in surface finishing and protection industries. They play a pivotal role in ensuring the successful application of coatings, such as paints, powders, or platings, and in enhancing the resistance of metal surfaces to corrosion. These processes involve cleaning, removing contaminants, and forming a phosphate conversion coating on the metal surface, providing an optimal foundation for subsequent coating applications.

Metal Degreasing:

Purpose: Metal degreasing is the process of removing oils, greases, dirt, and other organic contaminants from the metal surface. These contaminants can hinder coating adhesion and lead to poor quality finishes.

Methods:

Solvent Cleaning: Solvents, such as hydrocarbons or chlorinated compounds, are used to dissolve and remove organic contaminants from the surface. This method is effective but can be environmentally unfriendly due to volatile organic compound (VOC) emissions.

Aqueous Cleaning: Water-based solutions with detergents or surfactants are used to emulsify and remove organic contaminants. This method is more environmentally friendly and is commonly used in industries aiming to reduce VOC emissions.

Vapor Degreasing: This method involves the use of solvent vapor to clean the metal. The vapor condenses on the surface and dissolves contaminants, which then drip off.

Phosphatizing:

Purpose: Phosphatizing is the process of applying a phosphate conversion coating to a metal surface. This coating serves as a foundation for improved coating adhesion and enhances corrosion resistance.

Methods:

Zinc Phosphating: In this process, a zinc phosphate conversion coating is formed on the metal surface. This coating not only enhances adhesion but also provides a degree of corrosion protection.

Iron Phosphating: Iron phosphate coatings are formed using iron or ferrous materials. They provide better corrosion resistance compared to zinc phosphates but are often used as a base for subsequent paint coatings.

Process:

Cleaning: Before phosphating, the metal surface must be thoroughly cleaned to remove all contaminants.

Phosphating Solution: The metal is then immersed in a phosphating solution, which contains phosphate ions and accelerators. The solution reacts with the metal surface to form a phosphate coating.

Conversion Coating: The phosphate coating chemically bonds to the metal surface, creating a rough and porous layer that improves coating adhesion.

Rinsing and Drying: After the phosphating reaction, the metal is rinsed to remove excess chemicals and is then dried before proceeding with further processes.

Advantages of Metal Degreasing and Phosphatizing:

Enhanced Adhesion: Removing contaminants and forming a phosphate conversion coating improve the adherence of subsequent coatings, ensuring a longer-lasting finish.

Corrosion Resistance: Phosphate coatings act as a barrier against corrosion, extending the lifespan of the coated metal.

Surface Preparation: Properly prepared surfaces ensure that coatings are applied evenly, reducing the likelihood of defects and imperfections.

Uniformity: These processes provide uniform coverage even on complex surfaces, ensuring consistent protection.

Applications:

Metal degreasing and phosphatizing are used in various industries, including:

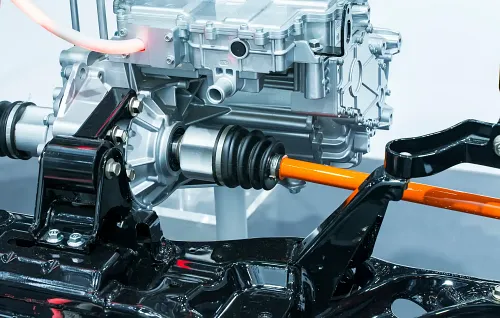

Automotive: Vehicle components, chassis, and structural parts benefit from enhanced corrosion resistance provided by these processes.

Aerospace: Aircraft parts and components require robust corrosion protection due to their exposure to harsh environmental conditions.

Industrial Equipment: Machinery, tools, and equipment used in manufacturing and industrial settings can be protected against corrosion and wear.

Metal degreasing and phosphatizing are integral steps in surface preparation, ensuring optimal adhesion and corrosion protection in various industries. These processes lay the foundation for high-quality coatings and extend the lifespan of metal components in demanding environments. Contact our specialists in Monterrey about metal preparation for painting for your project.

Contact us

Are you ready to discuss how we can help you achieve your manufacturing goals? Fill out this form, and we will get back to you.

Monterrey, Mexico

Ave. La Silla Apodaca #101

Parque Industrial La Silla Apodaca

Apodaca, NL, Mexico CP. 66648

Phone: +1 803-918-5599

Metal Coating Services Monterrey Mexico Prince Manufacturing Location

Already Trusted Us