E-coating Monterrey Prince Manufacturing Monterrey, Mexico

E-coating Coating

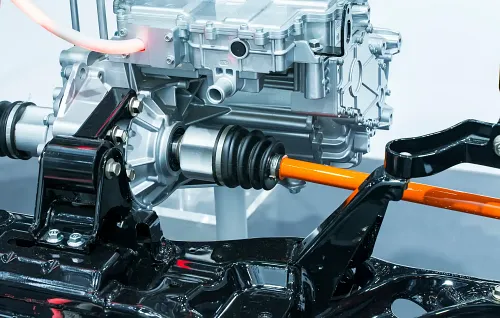

E-Coating: Enhancing Protection through Electrodeposition E-coating, short for electrodeposition coating or electrophoretic coating, is a widely used method in the realm of industrial finishing and surface protection. We offer this advanced coating process here in Monterrey, MX Prince Manufacturing facility. This process involves the application of a protective layer of paint or other coatings to a substrate through the utilization of electrical currents. E-coating provides a range of benefits, including enhanced corrosion resistance, improved adhesion, and even coverage, making it a staple in industries such as automotive, aerospace, appliances, and more.

- Automotive: E-coating plays a crucial role in the automotive sector, protecting vehicle bodies and components from rust and corrosion.

- Appliances: Household appliances such as washing machines, refrigerators, and ovens benefit from e-coating’s protective properties, as they are exposed to moisture and harsh chemicals.

- Aerospace: Critical aircraft components are often e-coated to withstand the demanding conditions of flight, including exposure to high altitudes and varying weather conditions.

- Furniture: Metal furniture items, such as outdoor seating and tables, are coated using this method to ensure their durability against the elements.

Challenges: While e-coating offers numerous advantages, it’s not without its challenges. Managing the electrical current, maintaining the proper bath composition, and addressing potential defects like “fish-eye” imperfections require expertise and careful monitoring to ensure consistent quality like we employ here at Prince Manufacturing Monterrey.

Contact us

Are you ready to discuss how we can help you achieve your manufacturing goals? Fill out this form, and we will get back to you.

Monterrey, Mexico

Ave. La Silla Apodaca #101

Parque Industrial La Silla Apodaca

Apodaca, NL, Mexico CP. 66648

Phone: +1 803-918-5599

Metal Coating Services Monterrey Mexico Prince Manufacturing Location

Already Trusted Us