Metal Stamping Stamping for Your Manufacturing Needs

Outsource Your Metal Stamping to a Trusted Partner – Precision Metal Stamping Services

At Prince Manufacturing, we specialize in delivering high-quality, precision metal stampings through the use of advanced high-speed presses and the expertise of our highly skilled technicians. Our extensive contract manufacturing capabilities enable us to produce metal stampings of virtually any shape, using a wide variety of metals, alloys, or composite materials. By outsourcing your metal stamping needs to us, your business will gain a competitive edge, benefiting from our commitment to precision, innovation, and cost efficiency.

Our Services Include:

Metal Fabrication – Metal Stamping – Coating – E-coating – Powder Coating – CARC – Fluidizing Powder Coating – Liquid Coating – Assembly – Metal Plating – Sequencing & Kitting – and more.

See customer success and companies that already trusted us.

Why Outsource Metal Stamping to Prince Manufacturing?

When you choose Prince Manufacturing as your metal stamping partner, you’re not just outsourcing a process—you’re gaining a strategic ally. We provide a full range of services that seamlessly integrate with your production workflow, from design to shipping. Our comprehensive metal stamping services include:

- Precision High-Speed Metal Stamping: Our advanced stamping presses can handle high-volume production runs with unmatched accuracy and speed, ensuring every part meets your exact specifications.

- Material Versatility: Whether your project requires standard metals, high-performance alloys, or even precious metals, we have the expertise to stamp from virtually any material, accommodating a wide variety of applications.

- Integrated Manufacturing Solutions: Beyond stamping, we offer value-added processes such as welding, assembly, and finishing, combining your metal stampings with other manufacturing stages to create streamlined, end-to-end production solutions.

- Expertise with Complex Alloys: Our team has extensive experience working with high-performance and precious metal alloys, ensuring superior results even for the most demanding applications.

- Strict Quality Control: We follow rigorous quality control measures throughout the stamping process to ensure consistent part accuracy, integrity, and reliability. With our advanced technology, we can meet even the most stringent industry standards.

Contact us. Free Consultation about your goals.

Ready to take your business to the next level? Fill out the form below, and let’s discuss achieving your goals together!

Industries We Serve

Our metal stamping services cater to a wide range of industries, including but not limited to:

- Automotive: Precision parts for engines, transmissions, and more.

- Aerospace: High-performance alloys for critical applications.

- Electronics: Metal stampings for electrical components and connectors.

- Medical Devices: Highly precise and durable stampings for medical instruments and equipment.

- Industrial Equipment: Durable, wear-resistant components for heavy machinery.

- And Others.

Advantages of Partnering with Prince Manufacturing

-

Cost Efficiency & Waste Reduction: By continuously adopting the latest technologies and optimizing our processes, we provide superior metal stamping services while driving down costs. Our focus on lean manufacturing practices helps eliminate waste and improve efficiency across the board.

-

Advanced Technology & Expertise: We invest in the latest metal stamping technologies, allowing us to produce parts with exceptional precision and speed. Combined with the deep expertise of our team, we deliver high-quality results that meet or exceed customer expectations.

-

Scalable Production: Whether you need small batches or high-volume production runs, we have the capacity and flexibility to scale our operations according to your needs. Our high-speed presses and efficient workflows ensure quick turnaround times without sacrificing quality.

-

Commitment to Sustainability: Prince Manufacturing is dedicated to reducing environmental impact through energy-efficient practices and sustainable sourcing of materials. We work closely with our clients to meet both performance and sustainability goals.

Certified Quality and Compliance

Prince Manufacturing holds certifications that reflect our commitment to quality, safety, and compliance with industry standards. Our equipment and processes are regularly updated to meet the latest technological advancements, ensuring that we can deliver reliable and precise results for your projects. For a detailed list of our equipment and certifications, please visit our Equipment and Certifications page.

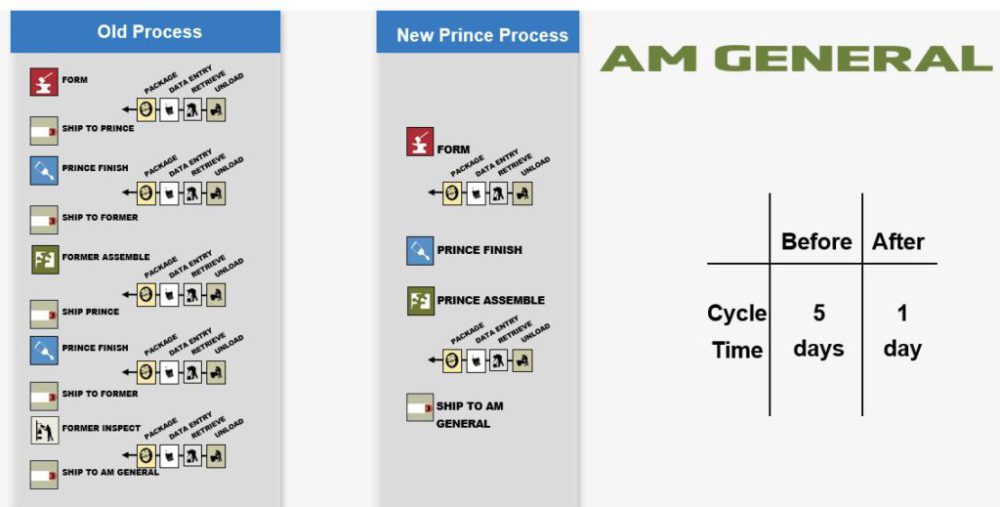

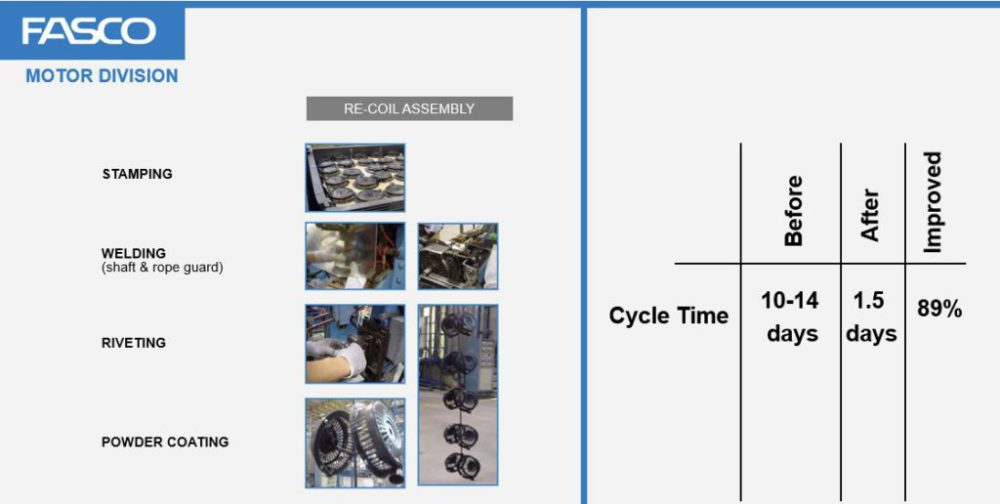

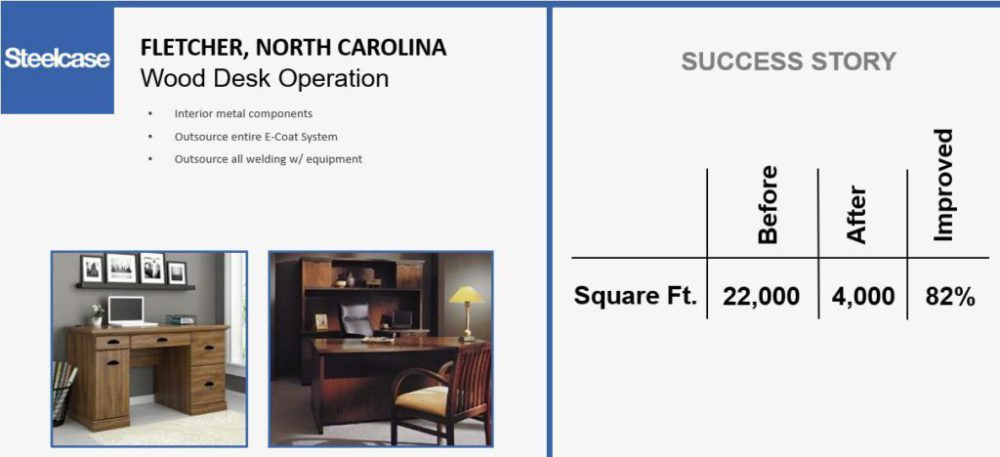

Customer Success Examples

One customer saw their square footage requirement drop from 600,000 square feet to 200,000 and their cycle time drop from five days to one—in addition to the other savings they realized. Below you can see 3 of our customers success stories. We reduced AM General’s manufacturing process from taking 5 days to 1 day. Fasco Motor Division process was reduced by 89% in length. From 10-14 days we reduced it to 1.5 days. Steelcase saw 82% reduction in required warehouse space from 22,000 sq ft to 4,000 sq ft. These are just a few examples.

Our Core Contract Manufacturing Services

Contract

Metal Fabrication

Contract

Sheet Metal Forming

Contract

Metal

Stamping

Contract

Assembly

Services

Contract

E-coating

Services

Contract

Metal

Coating

Contract

CARC

Painting

Contract

Powder

Coating

Contract

Fluidized Powder Coating

Contract

Liquid

Painting

Contract

Metal

Plating

Contract

Sequencing

Services

Shelter Services

Manufacturing in Mexico

Contract

Process Outsource

Contract

Supply Chain Management

Contract