Nickel Plating Services Nickel Plating: Precision, Protection, Perfection.

Custom Nickel Plating

At Prince Manufacturing, we offer nickel plating services as a part of the end-to-end contract manufacturing solutions tailored to your unique needs. With over 50 years of experience, state-of-the-art facilities, and a commitment to excellence, we ensure your products are manufactured to the highest standards, on time, and within budget.

Our Services Include:

Metal Fabrication – Metal Stamping – Coating – E-coating – Powder Coating – CARC – Fluidizing Powder Coating – Liquid Coating – Assembly – Metal Plating – Sequencing & Kitting – and more.

Nickel plating is a versatile and durable surface finishing process that enhances the properties of various components across multiple industries. At Prince Manufacturing, we offer state-of-the-art Nickel plating services designed to improve the corrosion resistance, conductivity, and aesthetic appeal of metal parts.

Key Features

- Corrosion Resistance: Nickel plating provides excellent protection against rust and corrosion, significantly extending the lifespan of metal components.

- Enhanced Conductivity: Ideal for electronic and electrical applications, Nickel plating enhances electrical conductivity, ensuring optimal performance of components.

- Durability: The plated surface is hard and wear-resistant, making it suitable for parts subjected to heavy use or harsh environments.

- Aesthetic Appeal: Nickel plating delivers a smooth, shiny finish that enhances the visual appeal of the components.

Contact us. Free Consultation about your goals.

Ready to take your business to the next level? Fill out the form below, and let’s discuss achieving your goals together!

Applications

Nickel plating is used across various industries to improve the functionality and appearance of metal parts. Key applications include:

- Automotive Industry: Used for decorative purposes, as well as to enhance the durability and corrosion resistance of components such as bumpers, rims, and engine parts.

- Electronics and Electrical Equipment: Essential for plating connectors, circuit boards, and other components that require excellent conductivity and resistance to oxidation.

- Aerospace and Defense: Provides a durable, corrosion-resistant coating for parts exposed to extreme conditions.

- Medical Devices: Ensures the longevity and sterility of surgical instruments and medical equipment.

- Renewable Energy Sector: Enhances the durability and efficiency of components in solar panels, wind turbines, and energy storage systems.

Technical Specifications

- Coating Thickness: Customizable from 0.5 microns to several millimeters, depending on the application requirements.

- Types of Nickel Plating:

- Electroless Nickel Plating: Provides uniform coating thickness and excellent corrosion resistance without the need for an electrical current.

- Electrolytic Nickel Plating: Offers a high degree of control over coating thickness and surface finish, suitable for various industrial applications.

- Substrate Materials: Compatible with a wide range of materials, including steel, aluminum, copper, and brass.

- Finish Options: Available in bright, semi-bright, and matte finishes to meet specific aesthetic and functional requirements.

Quality Control

At Prince Manufacturing, we adhere to stringent quality control processes to ensure the highest standards of Nickel plating. Our quality assurance measures include:

- Thickness Testing: Ensuring consistent coating thickness across all parts.

- Adhesion Testing: Verifying the strong bond between the Nickel layer and the substrate.

- Corrosion Resistance Testing: Conducting salt spray tests to confirm the protective qualities of the plating.

Benefits of Choosing Prince Manufacturing

- Advanced Technology: Our state-of-the-art plating facilities and cutting-edge technology guarantee top-notch results.

- Expertise: Our team of skilled professionals has extensive experience in Nickel plating, ensuring high-quality and reliable service.

- Customization: We offer tailored solutions to meet specific customer requirements, from coating thickness to finish options.

- Quick Turnaround: Efficient processes and streamlined operations allow us to deliver Nickel plated components promptly.

To learn more about nickel and nickel plating, visit the Nickel Institute.

Contact Us

To learn more about our Nickel plating services and how we can support your specific needs, please contact us:

Already Trusted Us

Customer Success Examples

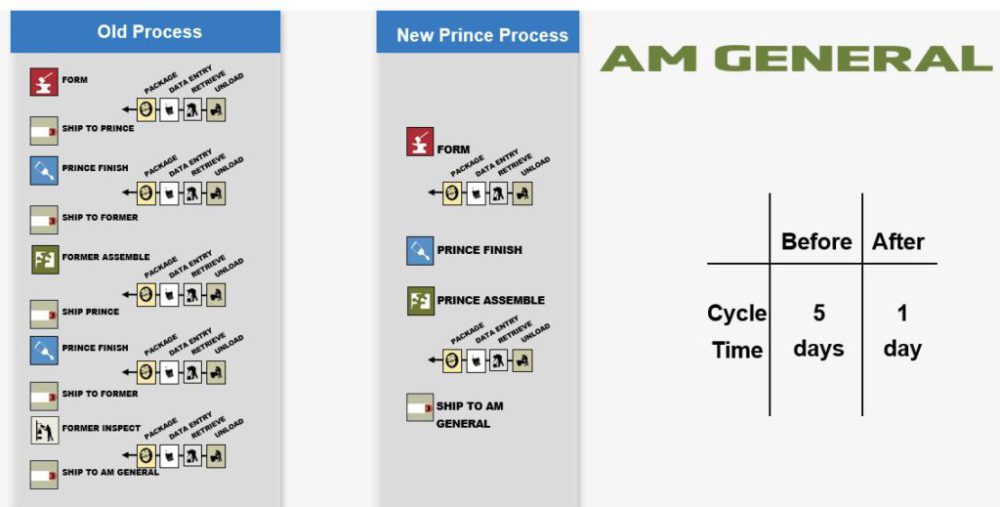

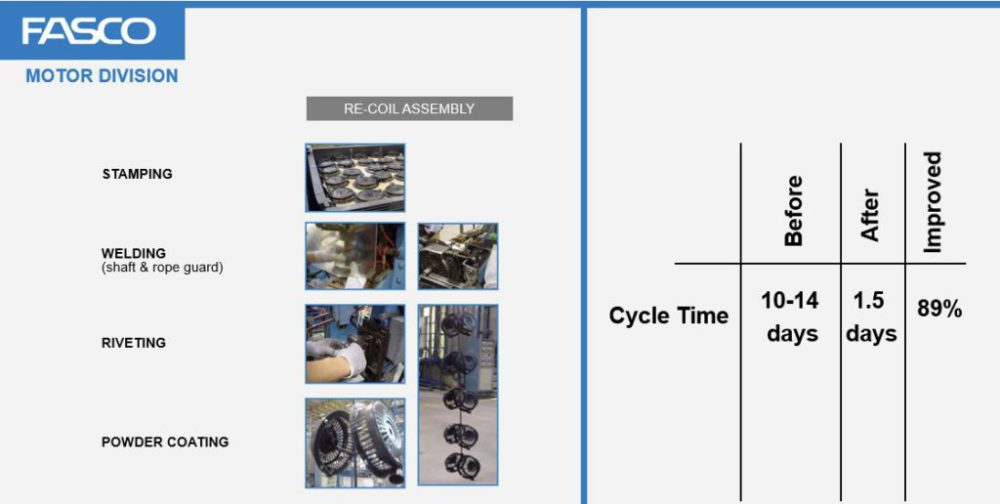

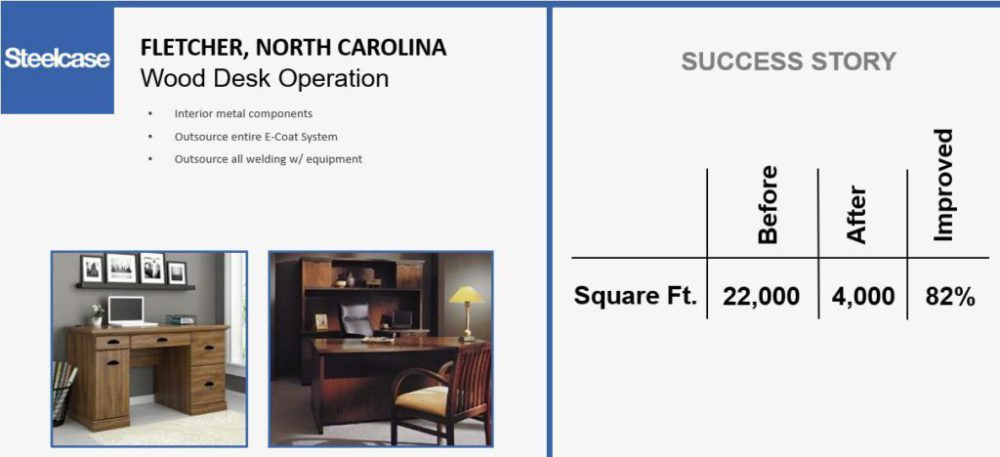

One customer saw their square footage requirement drop from 600,000 square feet to 200,000 and their cycle time drop from five days to one—in addition to the other savings they realized. Below you can see 3 of our customers success stories. We reduced AM General’s manufacturing process from taking 5 days to 1 day. Fasco Motor Division process was reduced by 89% in length. From 10-14 days we reduced it to 1.5 days. Steelcase saw 82% reduction in required warehouse space from 22,000 sq ft to 4,000 sq ft. These are just a few examples.

Our Core Contract Manufacturing Services

Contract

Metal Fabrication

Contract

Sheet Metal Forming

Contract

Metal

Stamping

Contract

Assembly

Services

Contract

E-coating

Services

Contract

Metal

Coating

Contract

CARC

Painting

Contract

Powder

Coating

Contract

Fluidized Powder Coating

Contract

Liquid

Painting

Contract

Metal

Plating

Contract

Sequencing

Services

Shelter Services

Manufacturing in Mexico

Contract

Process Outsource

Contract

Supply Chain Management

Contract