Contract Metal Painting Metal Finishing for Your Manufacturing Needs

Custom Metal Coating

At Prince Manufacturing, we offer end-to-end contract manufacturing solutions tailored to meet your unique needs. With over 50 years of experience, state-of-the-art facilities, and a commitment to excellence, we ensure that your products are manufactured to the highest standards, on time, and within budget.

Our Services Include:

Metal Fabrication – Metal Stamping – Coating – E-coating – Powder Coating – CARC – Fluidizing Powder Coating – Liquid Coating – Assembly – Metal Plating – Sequencing & Kitting – and more.

See customer success and companies that already trusted us.

Metal Finishing: Powder Coating, Liquid Coating, CARC, E-Coating, Fluidizing Powder Coating, Metal Plating

Highly technical composites require the technical coating solutions that Prince Manufacturing provides. Many companies have failed whereas Prince has succeeded with great quality solutions. We’d like a chance to prove that to you.

We’re never satisfied with the industry’s best. We also invest aggressively in research and development to improve product performance, value/cost structure, and environmental feedback. For example, please look at how we improved water usage in Mexico and in Indiana.

Best of all, Prince Manufacturing can meet your coating needs and fulfill other requirements, such as forming or assembly, under one roof—giving you greater control while streamlining and making the entire manufacturing process more efficient.

Contact us. Free Consultation about your goals.

Ready to take your business to the next level? Fill out the form below, and let’s discuss achieving your goals together!

Prince Manufacturing has unmatched experience in a number of different coating techniques, including:

Powder Coating

Powder coating offers a durable and attractive finish for metal surfaces. It provides superior resistance to chipping, scratching, and fading. Ideal for both indoor and outdoor applications, powder coating is an environmentally friendly option that eliminates the need for solvents. Learn more: Powder Coating

Liquid Coating

Liquid coating, also known as wet paint, is versatile and offers excellent coverage, especially for complex geometries. This process is perfect for projects requiring a thin, even coat and can be applied to a variety of metals. Learn more: Liquid Paint Coating

CARC Painting

Chemical Agent Resistant Coating (CARC) is essential for military applications. This specialized paint provides resistance to chemical and biological agents, ensuring the longevity and durability of the equipment in harsh environments. Learn more: CARC

E-Coating

E-coating, or electrocoating, involves immersing metal parts in a paint bath and applying an electrical current. This technique ensures even coating across the entire surface, including hard-to-reach areas, providing a high level of corrosion resistance. Learn more: E-Coating

Fluidizing Powder Coating

Fluidizing powder coating is a unique process that allows for the coating of complex shapes and is often used in high-volume production. It offers an even, durable finish that is resistant to wear and corrosion. Learn more: Fluidizing Powder Coating

Metal Plating

Metal plating involves the application of a metal layer onto a substrate for added protection, conductivity, or aesthetic appeal. Our plating services include a variety of options such as zinc, nickel, and chrome, tailored to meet specific industry needs. Learn more: Metal Plating

Industries Served

We cater to diverse industries, including automotive, aerospace, defense, Electrical Enclosures, EV, Electrification, Telcom, Heavy Truck, HVAC, Power Distribution, Power Sports, and consumer goods, providing tailored metal painting solutions that meet stringent industry standards.

Why Choose Us?

Our state-of-the-art facilities, experienced team, and commitment to quality make us a leading provider of metal painting services. We adhere to strict quality control processes to ensure every project meets or exceeds client expectations.

Types of Metal Finishing and Their Benefits

There are many different types of metal finishing, each with its own unique benefits. Here is a list of some of the most common types of metal finishing and the benefits that:

| Type | Benefits |

|---|---|

| Abrasive finishing | Abrasive finishing uses abrasives to remove material from the surface of a metal. This can be used to smooth out rough surfaces, remove blemishes, and create a desired finish. |

| Burnishing | Burnishing uses a burnishing tool to polish the surface of a metal. This can be used to create a smooth, reflective finish. |

| Electropolishing | Electropolishing uses an electric current to remove material from the surface of a metal. This can be used to create a very smooth, uniform finish. |

| Passivation | Passivation is a process that creates a protective layer on a metal’s surface. This can improve the metal’s corrosion resistance and appearance. |

| Plating | Metal Plating is a process of depositing a thin layer of metal onto the surface of another metal. This can be used to improve the corrosion resistance, wear resistance, electrical conductivity, and appearance of the metal. |

| Polishing | Polishing uses abrasives to create a smooth, shiny finish on the surface of a metal. This can be used to improve the appearance of the metal and make it easier to clean. |

Other types of metal finishing include:

- Brushing | Brushing uses a wire brush to remove material from the surface of a metal and create a brushed finish.

- Deburring | Deburring is the process of removing sharp edges from a metal. This can be done using a variety of methods, such as filing, sanding, or tumbling.

- Heat treatment | Heat treatment is a process of heating and cooling a metal to change its properties. This can be used to improve the strength, hardness, and toughness of a metal.

- Shot blasting | Shot blasting uses a stream of abrasive particles to remove material from the surface of a metal. This can be used to clean the surface of the metal, remove rust, and create a textured finish.

The benefits of metal finishing vary depending on the type of finishing used. However, some of the general benefits of metal finishing include:

- Improved appearance: Metal finishing can improve the appearance of metals by giving them a bright, shiny finish. This is important for metals that are used in decorative applications.

- Increased durability: Metal finishing can make metals harder and more durable. This is important for metals that are subject to wear and tear.

- Improved corrosion resistance: Metal finishing can help to protect metals from rust and corrosion. This is important for metals that are exposed to the elements or to harsh chemicals.

- Enhanced performance: Metal finishing can improve the performance of metals in certain applications. For example, electropolishing can improve the electrical conductivity of metals, while passivation can improve the wear resistance of metals.

Metal finishing is used in a wide variety of industries, including automotive, aerospace, electronics, construction, and manufacturing.

Contact us to learn how Prince Manufacturing can help you with your metal finishing project.

Already Trusted Us

Customer Success Examples

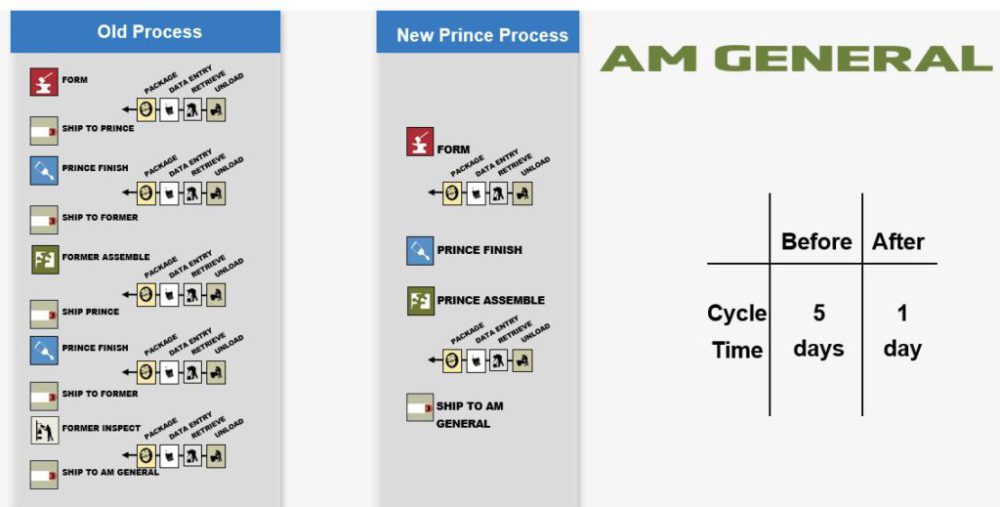

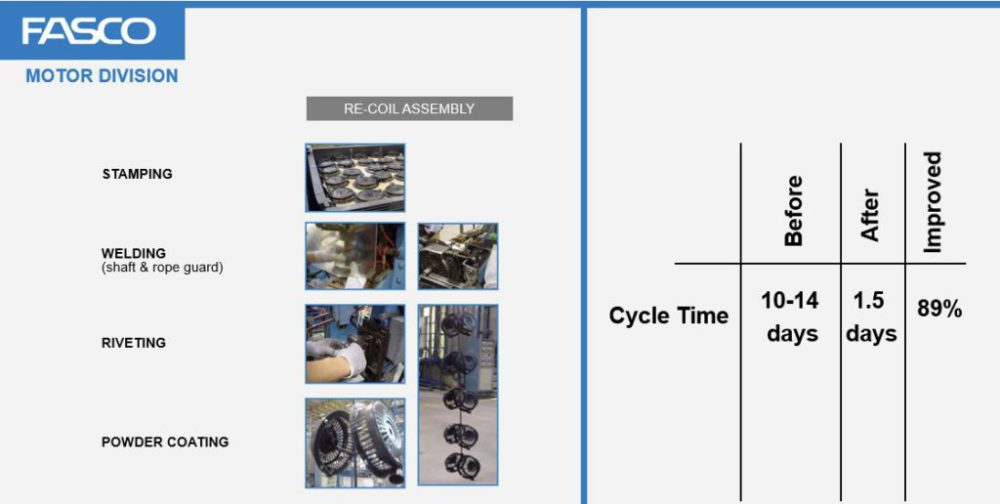

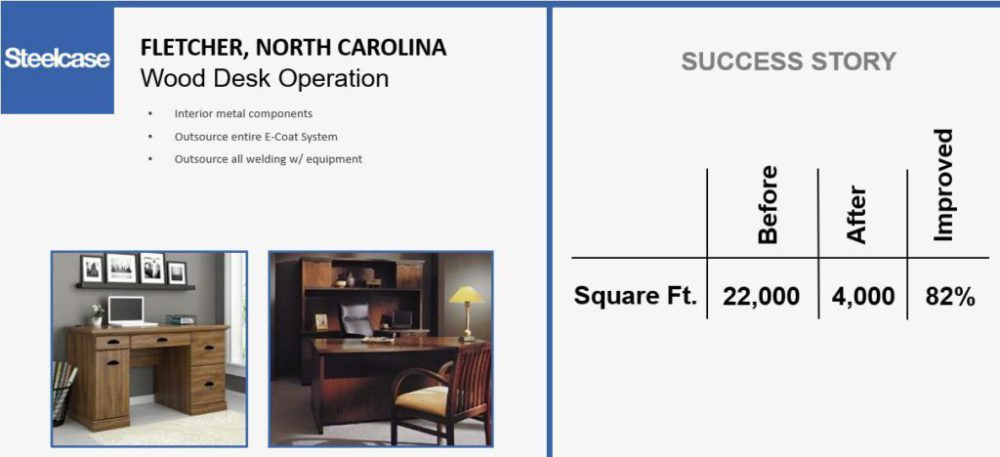

One customer saw their square footage requirement drop from 600,000 square feet to 200,000 and their cycle time drop from five days to one—in addition to the other savings they realized. Below you can see 3 of our customers success stories. We reduced AM General’s manufacturing process from taking 5 days to 1 day. Fasco Motor Division process was reduced by 89% in length. From 10-14 days we reduced it to 1.5 days. Steelcase saw 82% reduction in required warehouse space from 22,000 sq ft to 4,000 sq ft. These are just a few examples.

Our Core Contract Manufacturing Services

Contract

Metal Fabrication

Contract

Sheet Metal Forming

Contract

Metal

Stamping

Contract

Assembly

Services

Contract

E-coating

Services

Contract

Metal

Coating

Contract

CARC

Painting

Contract

Powder

Coating

Contract

Fluidized Powder Coating

Contract

Liquid

Painting

Contract

Metal

Plating

Contract

Sequencing

Services

Shelter Services

Manufacturing in Mexico

Contract

Process Outsource

Contract

Supply Chain Management

Contract