Sheet Metal Forming Services High-Precision Sheet Metal Forming for Custom Components Across Industries

Experts in Sheet Metal Fabrication

At Prince Manufacturing, we are experts in sheet metal forming and fabrication. Metal stamping and precision metal forming. Compared to casting and forging, sheet-metal parts offer the advantages of lightweight and versatile shape.

Our Services Include:

Metal Fabrication – Metal Stamping – Coating – E-coating – Powder Coating – CARC – Fluidizing Powder Coating – Liquid Coating – Assembly – Metal Plating – Sequencing & Kitting – and more.

See customer success and companies that already trusted us.

For more information, please see our list of Equipment and Certifications.

Capabilities

Prince Manufacturing offers advanced sheet metal fabrication capabilities, including precision laser cutting, bending, metal stamping, and welding. Our state-of-the-art equipment allows for high accuracy and efficiency, enabling the production of custom components tailored to client specifications across various industries. We are equipped to handle complex designs, small to large production runs, and multiple metal types, ensuring high-quality results.

With a focus on quality control and experienced teams, we provide reliable, scalable solutions for demanding applications.

Contact us. Free Consultation about your goals.

Ready to take your business to the next level? Fill out the form below, and let’s discuss achieving your goals together!

Customization

Customization in sheet metal fabrication is key to meeting specific design and functional requirements. At Prince Manufacturing, this involves leveraging advanced equipment and expert craftsmanship to create tailored components that align with unique client specifications. We can handle complex geometries, various metals, and intricate designs, ensuring each part is crafted to precise tolerances.

Our flexible production capabilities allow us to adapt quickly to design or order volume changes, making us an ideal partner for customized fabrication solutions.

Experience

Already Trusted Us

Customer Success Examples

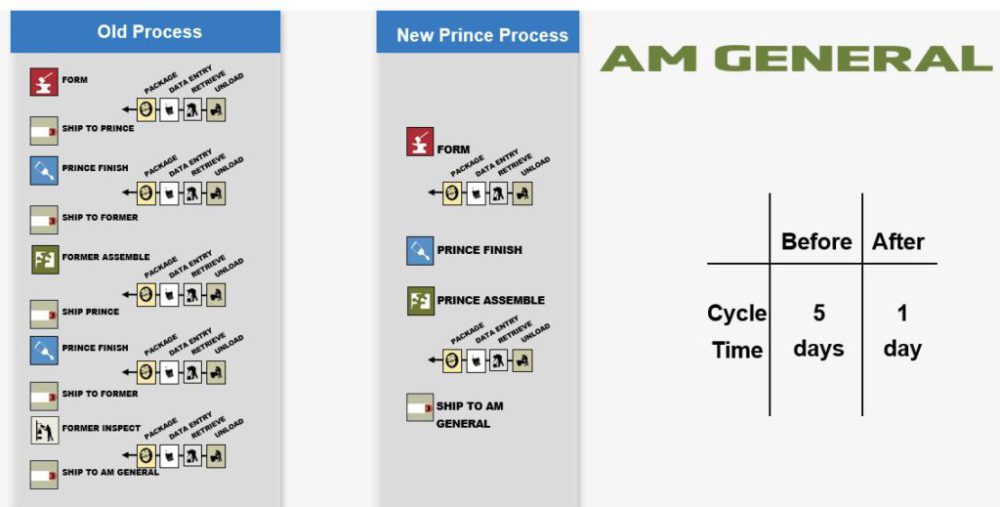

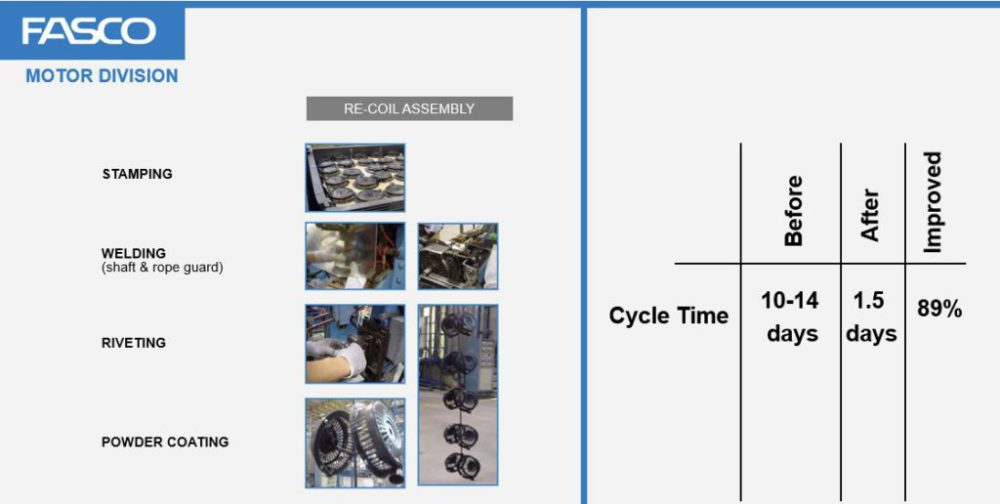

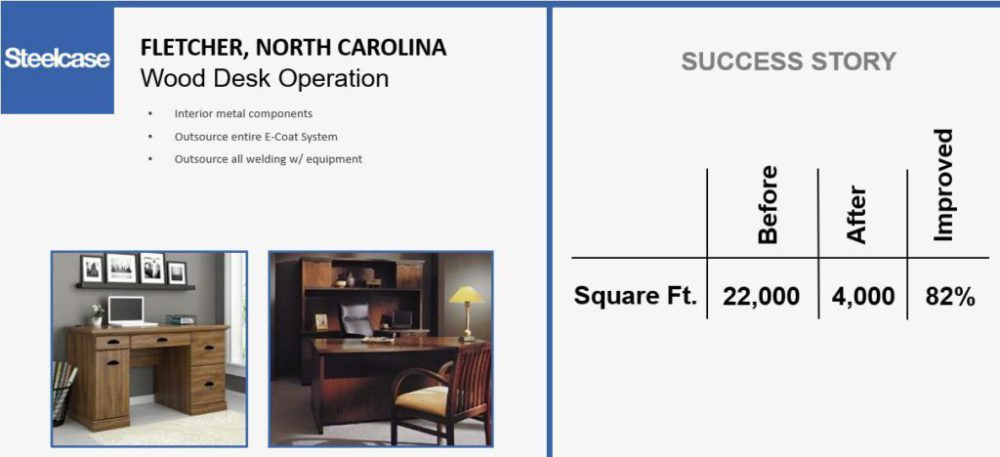

One customer saw their square footage requirement drop from 600,000 square feet to 200,000 and their cycle time drop from five days to one—in addition to the other savings they realized. Below you can see 3 of our customers success stories. We reduced AM General’s manufacturing process from taking 5 days to 1 day. Fasco Motor Division process was reduced by 89% in length. From 10-14 days we reduced it to 1.5 days. Steelcase saw 82% reduction in required warehouse space from 22,000 sq ft to 4,000 sq ft. These are just a few examples.

Our Core Contract Manufacturing Services

Contract

Metal Fabrication

Contract

Sheet Metal Forming

Contract

Metal

Stamping

Contract

Assembly

Services

Contract

E-coating

Services

Contract

Metal

Coating

Contract

CARC

Painting

Contract

Powder

Coating

Contract

Fluidized Powder Coating

Contract

Liquid

Painting

Contract

Metal

Plating

Contract

Sequencing

Services

Shelter Services

Manufacturing in Mexico

Contract

Process Outsource

Contract

Supply Chain Management

Contract

Shipping Logistics

Contact us for a free consultation

Ready to take your business to the next level? Fill out the form below, and let’s start a conversation about achieving your goals together!