Your Trusted Partner in Contract Manufacturing Services Streamline your production, reduce costs, and ensure quality with our expert contract manufacturing services.

Custom Manufacturing Solutions

At Prince Manufacturing, we offer end-to-end contract manufacturing solutions tailored to meet your unique needs. With over 50 years of experience, state-of-the-art facilities, and a commitment to excellence, we ensure that your products are manufactured to the highest standards, on time, and within budget.

Our Services Include:

Metal Fabrication – Metal Stamping – Coating – E-coating – Powder Coating – CARC – Fluidizing Powder Coating – Liquid Coating – Assembly – Metal Plating – Sequencing & Kitting – and more.

See customer success and companies that already trusted us.

Discover how our contract manufacturing solutions can elevate your business. Continue reading to learn more, or if you’re ready to start, fill out this form, and one of our experts will be delighted to discuss your project with you.

As companies struggle to compete in an increasingly aggressive global market, more and more category leaders are succeeding by focusing on their core competencies and outsourcing anything that directs valuable resources to anything else.

In short, a Contract Manufacturing partner like Prince acts as your factory:

- Producing and shipping a single part— a stamping or assembly or a door, for example,

- Completing a unique process, such as a coating process,

- Or manufacturing and assembling a complete product.

Contact us. Free Consultation about your goals.

Ready to take your business to the next level? Fill out the form below, and let’s discuss achieving your goals together!

The result? You save significant overhead dollars without ever sacrificing the quality that is at the heart of your brand integrity.

Working with a contract manufacturer has a wide range of significant advantages:

- Less square footage is required, reducing expenses,

- Management, expertise, and skilled labor is provided,

- All necessary certifications are on hand or can be acquired,

- Purchase power is combined with other projects to ensure maximum economies of scale,

- Handling import/export requirements,

- Shared healthcare and government compliance costs,

- Total overhead shared with other businesses,

- We ship products directly to your facility, distribution center, or to the end-user customer with your brand and packaging,

- Prince is “invisible” to your end-user customer.

State-of-the-Art Facilities

Prince Manufacturing operates six state-of-the-art factories across four strategic locations, enhancing their ability to deliver top-tier contract manufacturing services. In the United States, their advanced facilities are located in Garrett, Indiana, and Asheville, North Carolina. They also maintain a cutting-edge presence in El Paso, Texas, and expand their reach into Mexico with two high-tech plants in Ciudad Juárez and another in Monterrey.

These modern facilities specialize in various manufacturing processes, including metal fabrication, assembly, coating, and logistics. They ensure quality and efficiency while staying close to clients and optimizing operational costs.

Quality Assurance Guaranteed

Prince Manufacturing prides itself on its rigorous quality assurance standards, backed by a suite of prestigious certifications. They hold the TS 16949, ISO 14001, and ISO 9001:2015 certifications for their facilities in Ciudad Juárez, Asheville, and Garrett, as well as the QS 9000 certification. These certifications underscore their commitment to maintaining the highest quality in their manufacturing processes.

Moreover, Prince Manufacturing is a veteran-owned business and has earned TACOM certification for military-grade metal fabrication and coating. We also received the Intertek Workplace Conditions Assessment Achievement Award, further demonstrating their dedication to quality and excellence in every aspect of their operations.

For more details, visit Prince Manufacturing Certifications.

Cost-Effective Production

Through our robust contract manufacturing services, we offer cost-effective production. By leveraging advanced facilities and expertise, companies can significantly reduce production costs while maintaining high quality. Contract manufacturing allows businesses to avoid substantial investments in equipment, labor, and infrastructure, focusing instead on core competencies and strategic growth.

Prince Manufacturing’s state-of-the-art factories are strategically located to optimize logistics and supply chain efficiency, further reducing costs. Their comprehensive services, from metal fabrication to assembly and coating, ensure that clients receive high-quality products without the financial burden of in-house manufacturing.

On-Time Delivery

We are dedicated to ensuring on-time delivery for all clients, a critical aspect of contract manufacturing services. We can meet tight deadlines without compromising quality by maintaining a strategic network of state-of-the-art facilities and a streamlined supply chain. Our advanced planning systems and real-time tracking capabilities enable manage production schedules efficiently, ensuring that every project is completed and delivered as promised.

This commitment to punctuality helps clients maintain their own production timelines and market demands, making Prince Manufacturing a reliable partner for all manufacturing needs. For more details, speak with one of our experts.

In many cases, Prince Manufacturing can take over an existing facility, allowing you to continue operations without the expense and resource allocation of ongoing activities on your own. Here’s a brief case study about how we work with Siemens as a Contract Manufacturing partner.

Prince Manufacturing can also fold your requirements into one of our existing facilities. In some cases, the best solution may be for us to open a new plant to meet your highest expectations. In any case, we have the expertise and experience to be the best contract manufacturing partner in the industry.

Prince can also work with you as a Shelter Manufacturing partner.

Lean Management in Manufacturing

Contract Assembly

Supply Chain Management

Certifications

Equipment List

Check out our Comprehensive Guide to Smart Outsource Manufacturing.

Already Trusted Us

Our Core Contract Manufacturing Services

Contract

Metal Fabrication

Contract

Sheet Metal Forming

Contract

Metal

Stamping

Contract

Assembly

Services

Contract

E-coating

Services

Contract

Metal

Coating

Contract

CARC

Painting

Contract

Powder

Coating

Contract

Fluidized Powder Coating

Contract

Liquid

Painting

Contract

Metal

Plating

Contract

Sequencing

Services

Shelter Services

Manufacturing in Mexico

Contract

Process Outsource

Contract

Supply Chain Management

Contract

Shipping Logistics

Customer Success Examples

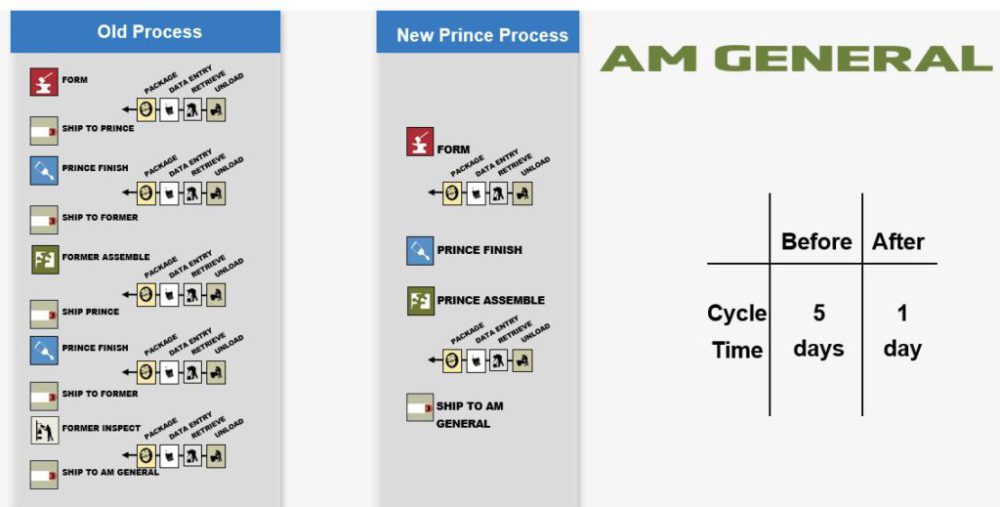

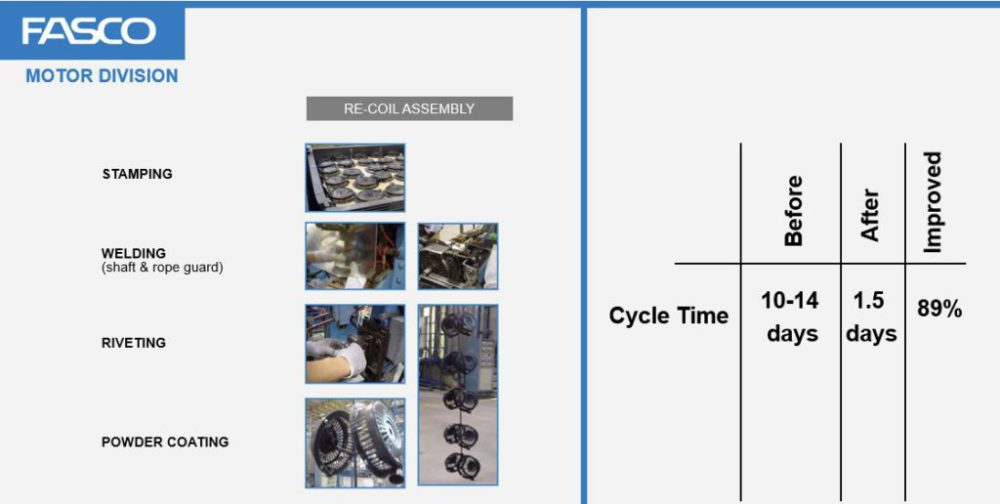

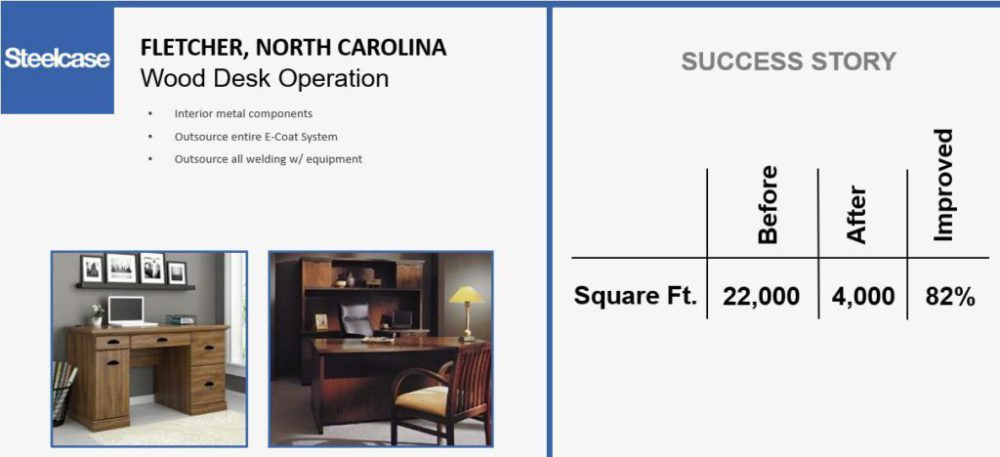

One customer saw their square footage requirement drop from 600,000 square feet to 200,000 and their cycle time drop from five days to one—in addition to the other savings they realized. Below you can see 3 of our customers success stories. We reduced AM General’s manufacturing process from taking 5 days to 1 day. Fasco Motor Division process was reduced by 89% in length. From 10-14 days we reduced it to 1.5 days. Steelcase saw 82% reduction in required warehouse space from 22,000 sq ft to 4,000 sq ft. These are just a few examples.