Fluidized Coating Monterrey Prince Manufacturing Monterrey, Mexico

Fluidized Coating

Fluidized Bed Coating: Enhancing Coating Efficiency and Uniformity

Fluidized bed coating is a specialized coating process utilized to achieve even and consistent coatings on three-dimensional objects, particularly those with complex shapes and intricate surfaces. This technique involves suspending a powdered coating material in an upward-flowing stream of air, creating a fluid-like state. The object to be coated is then immersed into this fluidized powder, allowing the particles to adhere to its surface uniformly. Fluidized bed coating is commonly employed for applications where a thick and robust coating is needed, offering advantages in terms of durability, adhesion, and efficiency.

The Fluidized Bed Coating Process:

The fluidized bed coating process consists of several steps:

Preparation: The substrate, often made of metal or heat-resistant plastic, is thoroughly cleaned and preheated. Preheating is crucial as it helps to ensure better adhesion and a more even coating.

Powder Fluidization: The coating powder, typically a thermoplastic or thermosetting polymer, is placed in a chamber equipped with a porous bottom. Compressed air is then forced through the porous bottom, creating an upward flow of air that suspends the powder particles and gives them a fluid-like behavior.

Coating Immersion: The preheated substrate is lowered into the fluidized bed of coating powder. The powder particles adhere to the substrate due to a combination of factors, including the heat of the substrate, the fluidized state of the powder, and electrostatic forces.

Coating Buildup: As the particles adhere to the substrate, a coating layer builds up. The thickness of the coating can be controlled by adjusting factors such as the immersion time, the powder particle size, and the fluidization parameters.

Curing: After the coating layer has been applied, the coated substrate is often heated to a temperature where the coating material melts and fuses together, forming a continuous and uniform coating. This step is known as curing.

Cooling and Solidification: Once the curing process is complete, the coated object is cooled, allowing the coating to solidify and become fully functional.

Advantages of Fluidized Bed Coating:

Uniformity: Fluidized bed coating provides exceptional coverage, even on intricate and irregular shapes, ensuring that all surfaces receive an even coating layer.

Thickness Control: The coating thickness can be controlled by adjusting factors such as immersion time and powder particle size, allowing for precise control over the final coating thickness.

Durability: The resulting coatings are known for their robustness and durability, making them suitable for applications requiring resistance to wear, corrosion, and other environmental factors.

Rapid Coating: Fluidized bed coating is a relatively fast process, making it suitable for mass production scenarios.

Minimal Waste: Excess powder that does not adhere to the substrate can be collected, recycled, and reused, minimizing waste and optimizing material usage.

Applications:

Fluidized bed coating finds applications in various industries, including:

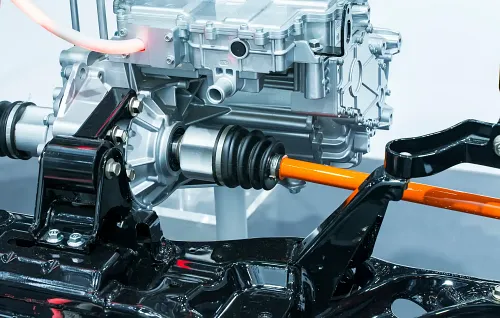

Automotive: Engine components, suspension parts, and other high-stress automotive components benefit from the durability and wear resistance of fluidized bed coatings.

Outdoor Equipment: Tools, playground equipment, and fences often require robust coatings to withstand outdoor exposure and usage.

Cookware: Non-stick cookware often uses fluidized bed coatings to provide a durable and heat-resistant surface.

Industrial Machinery: Equipment used in manufacturing processes often undergo fluidized bed coating to protect against wear, abrasion, and chemicals.

Fluidized bed coating is a valuable technique that offers a solution for achieving consistent and durable coatings on complex-shaped objects. Its ability to provide uniform coverage, along with its versatility and efficiency, makes it a preferred choice in industries where reliable and long-lasting coatings are essential. Our specialists are available to speak with you about your fluidized bed coating, especially in Monterrey location of Prince Manufacturing. Contact us.

Contact us

Are you ready to discuss how we can help you achieve your manufacturing goals? Fill out this form, and we will get back to you.

Monterrey, Mexico

Ave. La Silla Apodaca #101

Parque Industrial La Silla Apodaca

Apodaca, NL, Mexico CP. 66648

Phone: +1 803-918-5599

Metal Coating Services Monterrey Mexico Prince Manufacturing Location

Already Trusted Us