Sustainable Fluidized Powder Coating: A Green Solution for Modern Manufacturing

As environmental concerns grow, industries worldwide seek sustainable practices that reduce waste, conserve energy, and minimize their carbon footprint. Significant advancements have been made in surface finishing technologies, specifically sustainable fluidized powder coating. This eco-friendly coating process offers numerous benefits over traditional methods like liquid paints, making it an ideal choice for manufacturers striving for both performance and environmental responsibility.

In this blog post, we will explore how fluidized powder coating is sustainable, from its minimal waste generation to its energy efficiency and compliance with environmental regulations. We’ll also explore how it reduces hazardous waste, conserves water, and meets the increasing demand for eco-friendly products.

Fluidized Powder Coating Product Examples

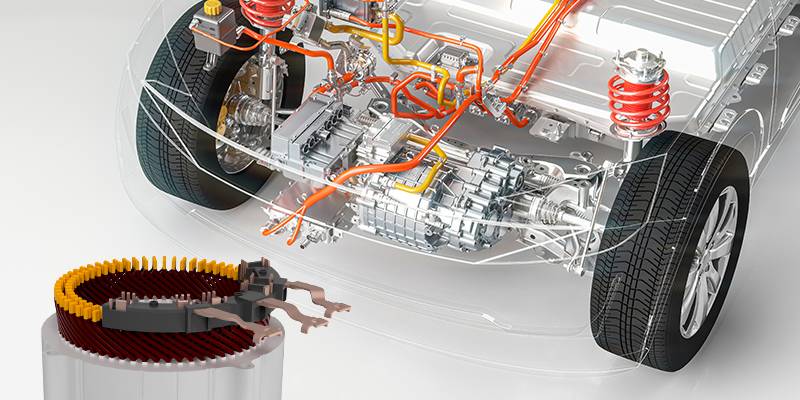

Bus Bars in Electric Vehicles (EVs):

Photo Description: Bus bars are essential components in EVs, facilitating efficient power distribution between the battery and various electrical systems.

Eco-Friendliness of Sustainable Fluidized Powder Coating

One of the standout qualities of sustainable fluidized powder coating is its eco-friendly nature. Unlike conventional liquid paint, powder coatings contain no solvents, which releases virtually no volatile organic compounds (VOCs) into the atmosphere. VOCs are harmful chemicals that contribute to air pollution and can lead to human health problems. By eliminating the need for solvents, fluidized powder coating significantly reduces the environmental impact associated with surface finishing.

In addition, powder coating materials are generally non-toxic, reducing the risk of harmful substances entering the environment during application or disposal. As regulations surrounding VOC emissions tighten, manufacturers turn to powder coating to stay compliant and reduce their environmental footprint.

Minimal Waste Generation

A key advantage of sustainable fluidized powder coating is its efficiency in material usage, leading to minimal waste. During the coating process, powder is applied using an electrostatic charge, ensuring that the coating adheres evenly to the surface of the coated object. Any excess powder that does not adhere can be easily collected and reused, resulting in virtually no waste.

Traditional liquid painting methods often suffer from overspray and wasted material, much of which cannot be recovered. In contrast, the powder used in fluidized powder coating can be recycled multiple times, making it highly resource-efficient. This ability to reclaim and reuse excess powder further enhances the process’s sustainability.

Electrical Enclosures:

Photo Description: These enclosures house electrical components, protecting them from environmental factors and ensuring safety.

Energy Efficiency

Fluidized powder coating also stands out for its energy efficiency. The curing process, which is necessary to harden the powder into a durable coating, generally requires lower curing temperatures compared to some liquid coatings. This results in reduced energy consumption during the manufacturing process.

In addition, modern and sustainable fluidized powder coating systems are designed to optimize energy use through more efficient heating methods and equipment. Manufacturers can lower their carbon emissions and operational costs by reducing the energy required to achieve a high-quality finish. These energy savings benefit the environment and improve a company’s bottom line, making powder coating a cost-effective, sustainable solution.

Durability and Longevity

Another factor contributing to the sustainability of fluidized powder coating is its durability and longevity. Powder-coated products are known for their excellent resistance to corrosion, abrasion, and harsh environmental conditions. This means coated products have a longer lifespan, reducing the need for frequent repainting or replacement.

The durability of powder-coated surfaces reduces the consumption of raw materials over time. By extending the lifecycle of coated products, manufacturers can reduce the overall environmental impact associated with production, transportation, and disposal. A longer-lasting product means fewer resources are used in the long run, contributing to a more sustainable manufacturing cycle.

Reduced Hazardous Waste

Sustainable fluidized powder coating significantly reduces hazardous waste generation compared to other coating methods. Traditional liquid paints often contain toxic chemicals such as heavy metals and solvents, which can pose risks during application and disposal. Wastewater from cleaning painting equipment is another environmental concern, as it can introduce hazardous substances into water systems.

In contrast, powder coatings are dry and free from solvents, eliminating the need for hazardous cleaning agents and reducing harmful waste production. This makes disposing of unused powder coating materials simpler and less damaging to the environment.

Furthermore, powder coatings do not require thinners or other hazardous chemicals, producing less hazardous waste throughout the coating process. This reduced hazardous waste is better for the environment and helps companies meet stricter environmental regulations.

Compliance with Environmental Regulations

Sustainability in manufacturing is increasingly tied to regulatory compliance, and fluidized powder coating excels in this area. Many countries and regions are imposing stricter limits on the emission of VOCs and hazardous air pollutants (HAPs) in response to growing concerns about air quality and environmental health. Because powder coatings are free of solvents and emit negligible VOCs, they easily comply with these regulations.

In addition, reducing hazardous waste generated during the powder coating process helps manufacturers meet waste management regulations and reduce their operations’ environmental impact. By adopting fluidized powder coating, companies can improve their sustainability practices and avoid the costly penalties and legal challenges associated with non-compliance.

Electrical Equipment:

Photo Description: This category includes various devices used in electrical systems, such as circuit breakers, relays, and distribution boards.

Sustainable Materials in Powder Coating

Another factor that makes sustainable fluidized powder coating sustainable is the nature of the materials used in the process. Many powder coating formulations use sustainable raw materials, such as bio-based or recycled polymers. These eco-friendly materials reduce the demand for virgin resources and lower the overall environmental impact of the coating process.

Some powder coatings are also designed to be more easily removed and recycled, allowing coated products to be repurposed at the end of their life cycle. Using sustainable materials in powder coating aligns with the principles of the circular economy, where products are designed for reuse, recycling, and minimal waste generation.

Water Conservation

Water usage is a significant concern in many industrial processes, particularly in traditional painting systems that require extensive equipment cleaning with water and solvents. Fluidized powder coating, however, is a dry process that does not require water for application or cleanup. This means that powder coating can significantly reduce water consumption compared to liquid coating processes.

By eliminating the need for water in the coating process, manufacturers can lower their overall water usage, contributing to more sustainable manufacturing practices and reducing the strain on local water resources. This is particularly important in regions facing water scarcity or where water conservation is a key priority.

Recyclability of Powder-Coated Products

A growing trend in sustainable manufacturing is the emphasis on recyclability, and fluidized powder-coated products excel in this area. Powder coatings are thermoset materials, which means they can be melted down and reused without degrading their quality. This allows for the recycling of powder-coated products at the end of their useful life, reducing the demand for new raw materials and minimizing waste.

In addition, because powder coatings are free from toxic solvents and heavy metals, they do not introduce harmful substances into recycling. This makes the recycling of powder-coated products easier and safer, further enhancing the sustainability of the process.

Meeting the Demand for Eco-Friendly Products

As consumer awareness of environmental issues grows, so does the demand for eco-friendly products. Manufacturers are increasingly required to adopt sustainable practices to meet this demand, and fluidized powder coating offers a clear advantage. The process’s eco-friendliness, durability, recyclability, and compliance with environmental regulations make it an ideal choice for companies seeking to align with the values of environmentally conscious consumers.

Sustainable fluidized powder coating allows manufacturers to produce high-quality, durable products while minimizing environmental impact. As sustainability continues to be a driving force in the marketplace, fluidized powder coating will play an essential role in helping companies meet the growing demand for eco-friendly solutions.

Fluidized Powder Coating at Prince Manufacturing

At Prince Manufacturing, we specialize in applying fluidized powder coating to a wide range of products for electrical insulation and durability. For example, we coat bus bars used in electric vehicles (EVs) to ensure safe and efficient power distribution. We also apply coatings to electrical enclosures used across industries, protecting critical components from environmental damage and electrical faults. Additionally, we provide coatings for transformers, switchgear, and various electrical equipment, delivering a sustainable and reliable solution for modern manufacturing needs.

Conclusion

Fluidized powder coating is a sustainable, eco-friendly alternative to traditional liquid painting methods. It offers numerous environmental benefits, including minimal waste, energy efficiency, reduced hazardous waste, and water conservation. The use of sustainable materials in powder coatings, combined with the recyclability of coated products, further enhances the environmental credentials of this process.

As regulations tighten and consumers demand greener products, sustainable fluidized powder coating provides manufacturers with a reliable, cost-effective, and sustainable solution that meets performance and environmental goals.