What Companies Use Contract Manufacturing?

Which companies use contract manufacturing? Is it just limited to auto parts manufacturing and a few other industries?

Questions like these are frequently asked. The answer to each of them is that all industries use contract manufacturing somehow. Most companies use contract manufacturing to access:

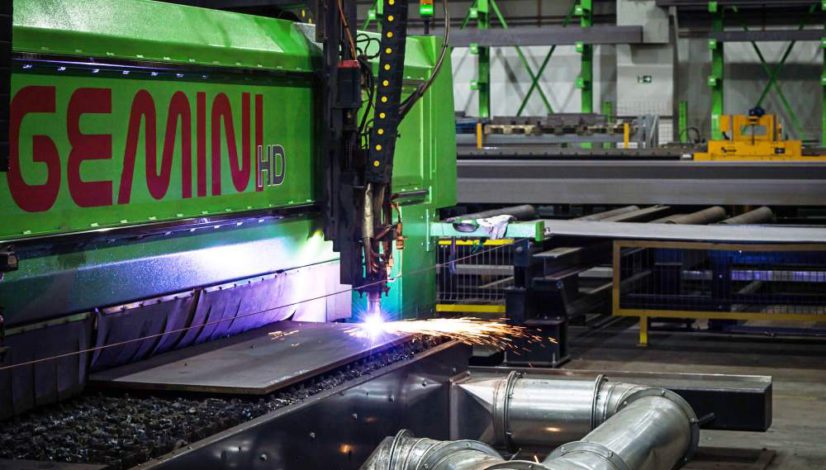

- Parts that require significant capital investments in equipment, such as metalworking or machining equipment.

- Parts that require specific manufacturing skills, such as mounting printed circuit boards.

- Some companies even have complete products that a contract manufacturer manufactures.

Contract manufacturing makes perfect sense for all kinds of businesses, including:

- Giants like Apple or General Motors

- Companies with lower volume products, such as medical device manufacturers

There are four good reasons to turn to contract manufacturing. Companies use it as a means by which they can:

- MINIMIZE CAPITAL INVESTMENT AND RISK

Building a factory or even simply retrofitting a production line requires a significant capital investment and many other resources. In addition to capital, these additional resources are needed:

- construction management

- manufacturing engineering

- financial analysis resources

- project management

In addition to the above resources, the project will be time-consuming. Investing a lot of resources can make sense for products that are already well established and have relatively low risk. Contract manufacturing makes a lot of sense for the less established products and more speculative products.

- MAINTAIN CERTAINTY OF COSTS AND DEADLINES

Even if a company has a lot of capital to build a factory, the cost of the final product is still uncertain. If there are cost overruns during construction or labor costs are higher than anticipated, that will increase the price of the product sold to customers. Production timelines are also at risk with any new project. Several factors can negatively affect production times:

- construction delays

- delays in the arrival and installation of manufacturing equipment

- hiring and training of new employees

Suppose manufacturers want to know exactly how much their products will cost and when they will be delivered. In that case, it is a good idea to hire a contract manufacturer with proven experience. The chosen service provider will take care of the calculations for companies and provide them with the costs and delivery times in the contract. It’s that easy, just the way it should be.

- FLEXIBILITY

Owning and running a dedicated factory requires a commitment of capital and human resources. Once these commitments are made, it is challenging to make changes. For example, it can be complicated to change:

- production processes

- manufacturing technologies

- tooling

- raw material suppliers

- manufacturing locations

No company wants to suffer the headaches of making changes in a factory, especially when it could be spending its time, energy, and financial resources on the central part of its business, such as sales. So when customers engage in a contract manufacturing relationship with a fabricator, they don’t have to worry about any internal changes (unless they directly affect their parts). The contract manufacturer’s responsibility is to uphold its end of the agreement. That means internal problems are irrelevant to companies that use a contract manufacturer as long as:

- They receive their parts on time.

- Parts meet the customers’ standards.

In addition, companies are entirely free to change manufacturers or move production to another country. However, they have to wait for their contract to end. Many companies audit their chosen manufacturers at the end of their contracts. If they determine that the contract manufacturer does not meet their standards, they have the option of awarding their business to another manufacturer. But if they use their factory, they cannot just change manufacturers. Instead of using contract manufacturing, they have to stay with their own factory and its problem.

Below is more information on why pursuing contract manufacturing can often be the smartest choice.

FLEXIBLE PRODUCTION VOLUMES

Contract manufacturing also offers flexible production volumes. There is no point in a company having its own factory if its parts don’t need full-time production. If a small volume of components is required, say, every two weeks, there is no point in investing in the factory, equipment, and labor needed to carry out the production

Many contract manufacturers, especially those located offshore, only ship large minimum orders. They have several reasons for this:

- They have to fill entire containers to ship

- They need to move their inventory of raw materials and subcomponents

- They do not have an existing production process for the same part or a similar part

The good news is that companies that engage in subcontract manufacturing, especially domestic companies, may offer much smaller production runs. Companies seeking to order small quantities of an item should look for a contract manufacturer that:

- Can ship orders by truck, rail, or plane

- Have low production costs and can pass the savings down

- Have low installation costs

- Can offer an accurate minimum order figure without much exchange of communications

- EXPERIENCE AND EXPERTISE IN CONTRACT MANUFACTURING

A popular saying goes: “Do what your company does best and outsource the rest.”

Is manufacturing not a company’s strong point? Then it makes sense for it to outsource production to a professional production organization. Opening a factory can mean exorbitant costs. Even businesses with pockets deep enough to build state-of-the-art factories shoulder a significant burden of risk. A company for which manufacturing is not its primary skill needs time to resolve initial difficulties before becoming as excellent and streamlined as an established manufacturer. Not having all of its ducks in a row will:

- affect a company’s overall success

- affect the quality of its products

Companies that wish to make a great first impression on their customers can choose to opt for a quality contract manufacturer that:

- have experience manufacturing their product or a similar product

- can start production quickly

- produces quality products

- employs skilled workers

- has quality certifications such as IATF 16949: 2016 and ISO 9001: 2015

Companies experienced in contract manufacturing know the ins and outs of quality production. So rather than reinventing the wheel, most companies would do much better hiring an established and experienced manufacturer to do their work for them.

WHITE LABEL BRAND OR CONTRACT MANUFACTURING?

When it comes to outsourcing manufacturing to another company, there are two basic options

White label manufacturing: White label manufacturing is when a company orders pre-made parts from another manufacturer and puts their brand on them. In this case, the customer does not have control over the following factors:

- The design of the pieces

- The price per unit

- The parties that purchase the same parts from the white label manufacturer

Contract Manufacturing: When companies choose this option, they hire a manufacturer to make parts to their specifications. In this case, they have sole ownership of the part and complete control over the following factors:

- The part design

- The materials used to make the part

- The production process

- Any improvement that they desire to make to the part or process

THE IMPORTANCE OF FINDING THE RIGHT CONTRACT MANUFACTURER

Not all companies that are engaged in contract manufacturing are the same. In theory, hiring a manufacturer often saves a lot of money for companies compared to opening a dedicated factory. However, this is true only if they hire the right contract manufacturer. Hiring the wrong contract manufacturer could cost companies a lot of money and trouble in the long run.

Smart companies do not just go for the lowest bidder. Instead, they thoroughly review each offer that they receive. This is the only way to identify a quality manufacturer that offers the best value and quality for money.

It is best for a business to opt for a contract manufacturer that offers the following benefits:

- A short supply chain

- Proximity to the customer (a flight of three to four hours at most)

- A highly skilled workforce

- Competitive labor costs

- Low shipping costs

- Strict intellectual property laws

- Socially responsible manufacturing

- Quality certifications

- A strong reputation in the industry

- Partnerships with reputable companies

- Continuous investment in equipment, facilities, and employees